PLC

PLC (Programmable Logic Control)

PLC is a digital electronic devices which have memory to store instructions to perform specific functions like sequence, timing, counting, arithmetic, and logic operation to control machines and processes.

Initially these types of functions were done by different relay logics. which usually required large space and maintenance. Moreover that system were not reliable. so with the thinking of that Relay system the PLC came into existence.

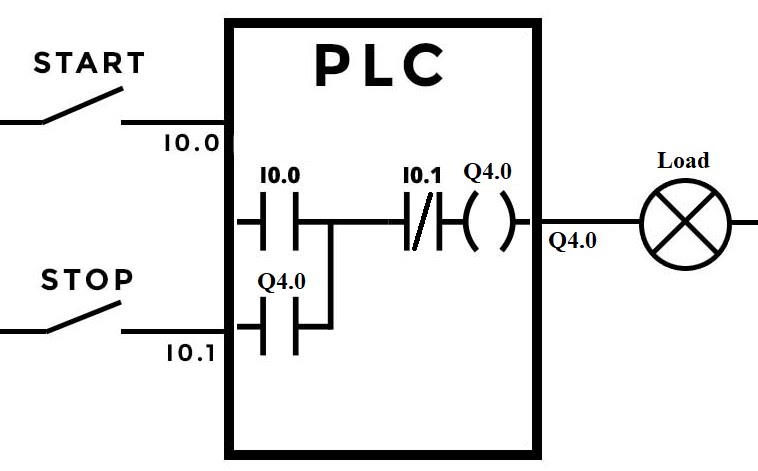

The above figure is a very basic block diagram description of PLC. The main parts of PLC are:

a) Central Processing Unit: This is the main part of PLC which performs all the operations. This is the brain of PLC

b) Input and Output modules: This two modules are directly connected with the process. Input modules takes the status of different inputs from field and send the status of those to the processing module. The different inputs might be Push button, limit switch, ON/OFF switch, Motor contact etc.

According to the status of the input signals and the program written into the processor the PLC processor produces the output signal which ultimately goes to output device via the output modules. So the function of the output modeles are to transmit the output signal from the processors to the output signal. The output device might be any type of ON/Off load or devices like solenoid valve, ON/OFF valve, pump, motor, light, fan etc.

C) Programmer: To operate the PLC there must have program to operate the PLC. That program must be written by some device which is called programmer. Those may be Laptop, Desktop or HMI. Program is written by the programmer and stored it into the processor RAM while PLC in ON for specific function.

D) Power Supply: Power supply is needed to the CPU as well as input output module. Supply voltage is 230 Voltage ac and 24 V dc is basically used for the input and output operation.

Basic Operation:

To perform a particular operation in plant by PLC first we have to write a program of that operation with suitable language using programmer. Then the program should be uploaded to the PLC. While PLC will be in RUN mode, it will check the status of different inputs and outputs. As per the program and these input output status PLC produces the output which is sent to the corresponding output devices via the output modeles.

Language uses in PLC programming:

Different PLC manufacturers use different language for programming. The most usable languages are;

*) Ladder

*) STL ( Statement List)

*) FBD (Functional Block Diagram)

Beyond this High level language like Fortran, Pascal, C, C++ etc might also be used for PLC programming.

Programming idea:

PLC

Reviewed by Suvodeep Roy

on

00:40

Rating:

Reviewed by Suvodeep Roy

on

00:40

Rating:

Reviewed by Suvodeep Roy

on

00:40

Rating:

Reviewed by Suvodeep Roy

on

00:40

Rating:

No comments: