Distributed Control System

Why

DCS

Ø For Total Plant

Automation

Ø For Higher

Productivity

Ø For Optimal

Process Control

Ø For Advance

Process Control

Ø For Regulatory

Compliance

Ø For Management

information System

Ø In Tune with

Global Requirement

What

is DCS System

A distributed

control system (DCS) is a specially designed automated control system that geographically and functionally distributed

all over the plant or control area. It is specially designed with redundancy and diagnostic

capabilities to improve control reliability and performance. It gives greater

flexibility to control distributed discrete field devices and its operating

stations

Distributed Control System is a specially designed

control system used to control complex, large and geographically distributed

applications in industrial processes. In this, controllers are distributed

throughout the entire plant area. These distributed controllers are connected

to both field devices and operating PCs through high speed communication

networks as shown in figure.

It differs from

the centralized control system wherein a single controller at central location

handles the control function, but in DCS each process element or machine or

group of machines is controlled by a dedicated controller. DCS consists of a large

number of local controllers in various sections of plant control area and are

connected via a high speed communication network.

In DCS control

system, data acquisition and control functions are carried through a number of

DCS controllers which are microprocessor based units distributed functionally

and geographically over the plant and are situated near area where control or

data gathering functions being performed as shown in the figure above. These

controllers able to communicate among themselves and also with other

controllers like supervisory terminals, operator terminals, historians, etc.

Distributed

individual automatic controllers are connected to field devices such as sensors

and actuators. These controllers ensure the sharing of gathered data to other

hierarchal controllers via different field buses. Different field buses or

standard communication protocols are used for establishing the communication

between the controllers. Some of these include Profibus, HART, arc

net, Modbus, etc.

DCS is most

suited for large-scale processing or manufacturing plants wherein a large

number of continuous control loops are to be monitored and controlled.

Nowadays, distributed control system has been found in many industrial fields

such as chemical plants, oil and gas industries, food processing units, nuclear

power plants, water management systems, automobile industries, etc.

Features of DCS:

Ø Reduce System Failure: Control

function is distributer among multiple CPUs (Field Control Stations). Hence

failure of one FCS does not affect the entire plant.

Ø Sophisticated

HMI: Use color CRT

with outstanding resolution. Trending, logging and graphical representation of

the HMI’s give effective user interface.

Ø Redundancy is

available at various level.

Ø Superior Reliability: Due to

redundancy and partitioning it ensures an outstanding level of reliability,

performance and expandability.

Ø

Broad Flexibility and

expandability: Structure of DCS can

be scalable based on the number of I/O’s from small to large system by accommodating additional stations.

Ø System security:

Security is also provided at different levels such as engineer level,

entrepreneur level, operator level, etc.

Ø Interlocks: Instruments

and interlocks are created by software. Generation and modification of the interlocks are very

flexible and simple

Ø Easy system maintenance: In the

unlikely event of failure, a self diagnostic function quickly locates the source of the problem,

Modular component design permits easy replacement .Maintenance and

troubleshooting become very easy.

Ø Minimize

production cost: To increase reliability, productivity and

quality while minimizing the production cost.

Ø

Powerful alarming

system of DCS helps operators to respond

more quickly to the plant conditions

Ø Cost

effective in the long run.

Ø Information

regarding the process is presented to the user in various format.

Ø Field wiring

is considerably less

Working & Operation of DCS System

The operation of

DCS goes like this; Sensors senses the process information and send it to the

local I/O modules, to which actuators are also connected so as to control the

process parameters. The information or data from these remote modules is

gathered to the process control unit via field bus. If smart field devices are

used, the sensed information directly transferred to process control unit via

field bus.

The collected

information is further processed, analyzed and produces the output results

based on the control logic implemented in the controller. The results or

control actions are then carried to the actuator devices via field bus. The DCS

configuring, commissioning and control logic implementation are carried at the

engineering station. The operator able to view and send control actions

manually at operation stations.

Architecture of DCS:

Architecture of DCS are almost same for all manufactures

with a little difference. Here is a

architecture of DCS from Yokogawa model CENTUM CS 3000

Human Interface Station

(HIS)

HIS is the

operating station, is used to operate,

monitor and control plant parameters. It can be a PC or any other

monitoring device that has a separate software tool on which operator can view

process parameter values and accordingly to take control action.

Operating

stations can be a single unit or multiple units where a single unit performs

functions like parameter value display, trend display, alarming, etc. while

multiple units or PCs performs individual functions such as some PCs display

parameters, some for trend archives, some for data logging and acquiring, etc.

Engineering Station (ENG)

Engineering

station is a PC with engineering capabilities used for system configuration and

system maintenance.

It is the

supervisory controller over the entire distributed control system. It can be a

PC or any other computer that has dedicated engineering software

This engineering

station offers powerful configuration tools that allow the user to perform

engineering functions such as creating new loops, creating various

input and output points, modifying sequential and continuous control

logic, configuring various distributed devices, preparing

documentation for each input/output device, etc.

Field Control Station

(FCS)

Field control station is the control unit for plant

process control. Varying with the application capacities and application

usages, there are several types of field control stations in the lineup. Controllers are distributed geographically in various

section of control area and are connected to operating and engineering stations

which are used for data monitoring, data logging, alarming and controlling

purpose via another high speed communication bus.

These

communication protocols are of different types such as foundation filed bus,

HART, Profibus, Modbus, etc. DCS provides information to multiple displays for

user interface.

Safety Control Station

(SCS)

Safety control

station is a controller of the ProSafe-RS TÜV SIL3 certified safety

instrumented system and it can be configured on the same network with CENTUM CS

3000 enabling HIS to monitor status of ProSafe-RS.

I/O Modules

Varieties of

Fieldnetwork I/O (FIO) are available in compact sizes to convert process

signals for FCS formats. Remote I/O are

for remote input and output that passes the field signals to FCS control unit

via remote buses.

Bus converter (BCV)

Bus converters

are used to link multiple domains.

System Integration OPC

Station (SIOS)

SIOS serves as a

gateway for connecting CENTUM CS 3000 R3 system and the OPC server to the

third-party PCS. It exchanges data, and acquires alarms and events through the

OPC server.

Control Network (Vnet/IP)

A real-time

control network for linking the stations such as FCS, HIS, and BCV.

Field Digital Network

CENTUM CS 3000

R3 supports field digital protocols such as FOUNDATION fieldbus, HART, PROFIBUS,

DeviceNet, Modbus, Modbus/TCP, EtherNet/IP and ISA100 wireless.

Controller

Yokogawa

controllers are designed for controlling and monitoring industrial plants which

must keep running non-stop in stabilized status with high reliabilities.

DCS Systems from Different Vendors

Some of the available DCS systems

include

Ø

ABB- Freelance 800F and 800xA, Freelance 2000

Ø

Yokogawa - Micro Excel ,

Centum Excel, Centum CS 1000, CS 3000, Centum VP

Ø

Honeywell -TDC 3000,

Experion PKS, TPS, GUS

Ø

Emerson - Delta V Digital

Automation

Ø

Siemens - Simatic PCS 7

Ø

Allen Bradley - NetLinx

Ø

Foxboro –I/A Series

Ø Moore

– APACS

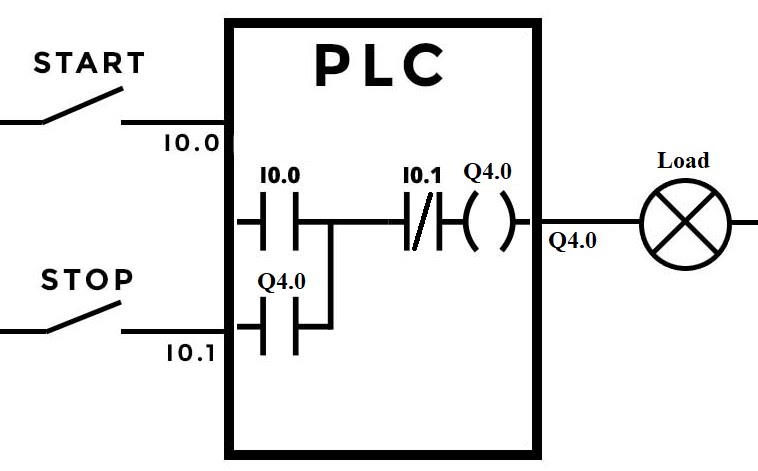

PLC

and DCS a Relative study:

Ø DCS

was developed as a replacement of ‘PID controller’, whereas PLC was developed

for the replacement of ‘Relay Logic’.

Ø PLC

is mainly used for small application, whereas DCS is used for large

application.

Ø Both

PLC and DCS are used for ‘logic’ and ‘continuous controller’. But PLC is mainly

used for Logic where as DCS is mainly used for continuous control.

Ø Scan

time of PLC is less than DCS. So PLC is faster than DCS.

Ø DCS

must have redundancy but PLC might not.

----------------------------------------------------------------------------------------------------------------

A

cabinet type and a rack-mount type of FCS are available from Yokogawa. Both

Vnet/IP and V net control networks can be used for configuring the system

networks. The dual-redundant design of the FCS processor modules, power supply,

I/O modules, and I/O networks achieve high availability of 99.99999%. The pair

& spare architecture is unique to Yokogawa that improves the stability of

process control.

A

cabinet type and a rack-mount type of FCS are available from Yokogawa. Both

Vnet/IP and V net control networks can be used for configuring the system

networks. The dual-redundant design of the FCS processor modules, power supply,

I/O modules, and I/O networks achieve high availability of 99.99999%. The pair

& spare architecture is unique to Yokogawa that improves the stability of

process control.

Process I/O Modules

Fieldnetwork I/O (FIO)

Yokogawa offers compact, cost-effective, and reliable I/O devices, targeted as the industrial standard.

Yokogawa offers compact, cost-effective, and reliable I/O devices, targeted as the industrial standard.

Subsystem Integration

In order to operate and monitor

the subsystems of the auxiliary devices controlled by programmable logic

controller (PLC), various types of analyzers and other instruments for the

integrated plant automation, FCS subsystem communication capability enables

connection with the subsystems, and also supports dual-redundant configuration.

The subsystems include Mitsubishi

MELSEC, Allen Bradley PLC-5 and SLC500, Modbus compatible devices, Siemens

SIMATIC, Omron SYSMAC, Yokogawa FA-M3, Darwin, and DAQSTATION and so on.

.

Human Machine Interface

Human Interface Station

(HIS)

Operators

access production control system via CENTUM CS 3000’s human interface station

(HIS) to make fast and intelligent decisions that maximize performance and

minimize risks.

Operators

access production control system via CENTUM CS 3000’s human interface station

(HIS) to make fast and intelligent decisions that maximize performance and

minimize risks.

Based on the ergonomic design

concept, the HIS can be selectable from desk top, open display style console,

and enclosed display style console types. Multiple monitors can be set, and

each one of the monitor displays multiple operation windows.

Dedicated Operation

Keyboard

The

operation keyboard is unique to Yokogawa. It consists of alphanumeric keys and

special operation keys which are assembled with the dustproof and drip-proof

flat keys. By assigning graphics to each button, operators can call up a

graphic by one touch.

The

operation keyboard is unique to Yokogawa. It consists of alphanumeric keys and

special operation keys which are assembled with the dustproof and drip-proof

flat keys. By assigning graphics to each button, operators can call up a

graphic by one touch.

Operation Windows

There

are different window like Graphic window, Control window, Overview window,

Trend window

|

|

Screen Modes

The ‘Multiple-window mode’ like

an office PC and the ‘Full-screen mode’ like the legacy operator console are

available for operation and monitoring environment.

Open Interface

The process control industry

standard open interface OPC (OLE for Process Control, or open productivity &

connectivity) is provided for collecting the process data, trend data and

messages.

Access Control

To prevent operation errors and

other problems and ensure the safety of the system, such as prohibiting

operations by unauthorized persons, limiting the ranges of operation and

monitoring, and restricting operator actions to the system, extensive security

functions are applied.

.

___________________________________________________________________________

Process

Control Unit of DCS

It is also called

as a local control unit, distribution controller, or process station. A

distributed control system can consists of one or more process stations that

can be extended with different types of I/O units. These controllers consist of

a powerful CPU module, field bus or communication module with extended field

bus capability and either direct or remote connected I/Os.

The field devices like sensors

and actuators are connected to I/O modules of this unit. Some field devices can

be directly connected to field bus (such as Profibus) without any I/O module,

which can be termed as smart field devices.

These units acquire the information

from various sensors via input module, analyze and process it based on the

control logic implemented and sends the output signals via output modules to

have control on actuators and relays.

This acts as process station,

which is responsible for acquiring and controlling the data from the process.

This unit consists of a power supply along with CPU section, Ethernet section,

Profibus section and remote communication interface unit for I/Os interfacing

as shown in the figure where first module is AC 800F unit and other one is

remote I/O (also called as communication interface module).

Communication System

The

communication medium plays a major role in the entire distributed control

system. It interconnects the engineering station, operating station, process

station and smart devices with one another. It carries the information from one

station to another. The common communication protocols used in DCS include

Ethernet, Profibus, Foundation Field Bus, DeviceNet, Modbus, etc.

It is not

mandatory to use one protocol for entire DCS, some levels can use one network

whereas some levels use different network. For instance, consider that field

devices, distributed I/Os and process station are interconnected with Profibus

while the communication among engineering station, HMI and process station

carried though Ethernet as shown in the figure below.

The major

advantage of DCS is the redundancy of some or all levels of the control

area. Most of the cases critical processes are installed with redundant

controllers and redundant communication networks such that problem in main

processing line should not affect the monitoring and control functions because

of the redundant processing section.

Smart or Intelligent Devices

The intelligent

field devices and field bus technology are advanced features of DCS technology

that replaces traditional I/O subsystems (I/O modules). These smart devices

embed the intelligence required for simple sensing and control techniques into

the primary sensing and actuating devices. And hence it replaces the need for a

DCS controller to perform routine sensing and control process.

These field devices can be

directly connected to field bus so that sourcing of multiple measurements to

the next higher level control station is possible via digital transmission line

by eliminating extraneous hardware such as local I/O modules and controllers.

Difference

between SCADA and DCS (DCS vs SCADA)

Although both

DCS and SCADA are monitoring and control mechanisms in

industrial installations, they have different goals. There exist some

commonality between DCS and SCADA in terms of hardware and its components,

however, there are certain requirements by the end applications that separates

a robust and cost-effective DCS from the viable SCADA system. Some of the

differences between DCS and SCADA are listed below.

1. DCS is process oriented, whereas SCADA is

data-gathering oriented. DCS emphasizes more on control of the process and it

also consists of supervisory control level. And as a part of doing so, it

presents the information to the operator. On the other hand, SCADA concentrates

more on acquisition process data and presenting it to the operators and control

centre.

2. In DCS, data acquisition and control modules

or controllers are usually located within a more confined area and the

communication between various distributed control units carried via a local

area network. SCADA generally covers larger geographical areas that use

different communication systems which are generally less reliable than a local

area network.

3. DCS employs a closed loop control at process

control station and at remote terminal units. But in case of SCADA there is no

such closed loop control.

4. DCS is process state driven where it scans the

process in regular basis and displays the results to the operator, even on

demand. On the other hand, SCADA is event driven where it does not scan the

process sequentially, but it waits for an event that cause process parameter to

trigger certain actions. Hence, DCS does not keep a database of process

parameter values as it always in connection with its data source, whereas SCADA

maintains a database to log the parameter values which can be further retrieved

for operator display and this makes the SCADA to present the last recorded

values if the base station unable to get the new values from a remote location.

5. In terms of applications, DCS is used for

installations within a confined area, like a single plant or factory and for a

complex control processes. Some of the application areas of DCS include

chemical plants, power generating stations, pharmaceutical manufacturing, oil

and gas industries, etc. On the other hand SCADA is used for much larger

geographical locations such as water management systems, power transmission and

distribution control, transport applications and small manufacturing and

process industries.

In spite of these major differences, the

modern DCS and SCADA systems come with common standard facilities while dealing

process plant automation. However, the choice between DCS and SCADA depends on

its client and end application requirement. But if the client choice between

these two, by gaining equal requirement from the process, DCS is the economical

choice as it help to reduce the cost and offer better control.

Foxboro I/A Series

The following figure is the basic

architecture of Foxboro I/A Series system

Siemens PCS7

The following figure is the basic

architecture of Siemens PCS7

Honeywell Experion PKS

The following figure is the basic

architecture of Honeywell Experion PKS

Honeywell TDC3000

The following figure is the basic

architecture of Honeywell TDC3000

Honeywell Total Plant

Solutions (TPS)

The following figure is the basic

architecture of Honeywell TPS

Yokogawa Centum CS3000

The following figure is the basic

architecture of Yokogawa Centum CS3000

What

is Distributed Control System

7

Important features of DCS

•

To handle complex processes:

In

factory automation structure, PLC-Programming Logic

Controller is used to

control and monitor the process parameters at high speed requirements. However

due to limitation of number of I/O devices, PLC’s cannot handle complex

structure.

System

redundancy:

System

Redundancy

CENTUM CS3000 R3

Application of Windows

Technology

With Windows Remote Desktop

capability, plant operation, monitoring, and engineering can be performed from

a personal computer in your office or at a remote field location without any

additional software.

Remote Operation and

Monitoring

The same HIS displays in the control room can be shown on the PC in your office. For production facilities in remote locations around the world, remote operation and monitoring can be simply structured.

The same HIS displays in the control room can be shown on the PC in your office. For production facilities in remote locations around the world, remote operation and monitoring can be simply structured.

Remote Engineering

The engineering work for modification can be performed remotely via a network, eliminating the need for dispatching engineers and reducing both maintenance and engineering cost.

The engineering work for modification can be performed remotely via a network, eliminating the need for dispatching engineers and reducing both maintenance and engineering cost.

DCS

Reviewed by Suvodeep Roy

on

16:26

Rating:

Reviewed by Suvodeep Roy

on

16:26

Rating:

Reviewed by Suvodeep Roy

on

16:26

Rating:

Reviewed by Suvodeep Roy

on

16:26

Rating:

No comments: